This page displays some information on equipment used by the SADF during the Border War. Please note that these are only some of the weapons and gear with which South African soldiers trained. For obvious reasons this page does not intend listing all the weapons and equipment used in the SADF. Check out the SADFLinks page for more comprehensive websites about South African made equipment. |

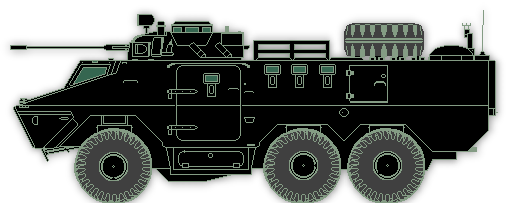

| Ratel 20 IFV |

|

The Ratel 20 is a homegrown South African 6x6 infantry fighting vehicle and carries a crew of 11 men (driver, gunner, commander, AA gunner, and 7 riflemen. Entry/exit is via a rear door or two side doors. There are also escape hatches in the roof and turret. Main armament is a turret-mounted 20mm cannon. Secondary armament consists of a 7.62mm co-ax MG and two 7.62mm AAMGs – one on a pintle mount on the turret and one on a small cupola at the rear of the vehicle. Additionally, there are four firing ports on each side of the vehicle. Armour is maximum 20mm thick, and is well-sloped all round. The engine and automatic transmission allow a maximum road speed of around 105km/h (65mph) with a range of about 1000km (620 miles). Variants include an armoured command vehicle equipped with a 12.7mm machine gun or a 20mm gun, a missile launcher, a 60mm and 81mm mortar, a 90mm gun as well as logistic and recovery vehicles. A combat loaded Ratel weighs in at 18 tons, is extremely versatile off-road and has been the basic infantry fighting vehicle of mechanised infantry groups in the Army for a number of years. |

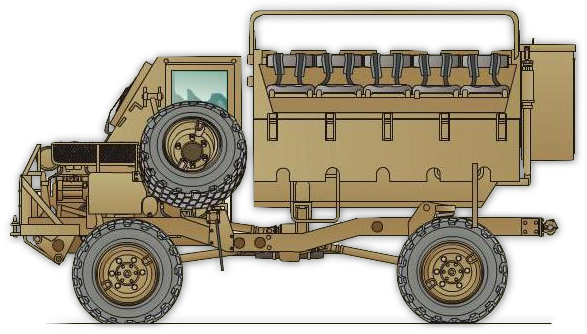

| Buffel Mine Protected APC |

|

The Buffel 4×4 vehicle was developed in the 1970s under the leadership of ARMSCOR (Armaments Corporation of South Africa) to meet the operational requirements for a mine protected Armoured Personnel Carrier (APC) for the South African Army, mainly infantry units. It is estimated that around 2,400 were built for the home and export markets before production was completed. These are still used in declining numbers by the South African Army. Description: The Buffel uses a German Mercedes-Benz UNIMOG Model 416/162 series 4 × 4 chassis that was originally developed for a wide range of civil and military roles. It should be noted that production of this chassis was completed many years ago. The all-welded steel armour hull has a V-shape to provide maximum possible protection against anti-tank mines. The Buffel was designed with a robust wedge shaped body that deflects the pressure wave and reduces the amount of energy transferred from the explosion to the vehicle. The effect of an explosion is also reduced in accordance with the distance or height of the target from the point of detonation. The rear troop compartment has an open top with the 10 infantrymen seated five down either side back to back facing outwards. Each seat is provided with a full seat belt harness and the seats have been specially designed to absorb as much as possible of the shock in the event of a mine detonation. The only means of entry and exit is by climbing over the sides of the hull, which is provided with steps. The hull sides are hinged at the lower part and can be open outwards to load equipment and supplies. A strong longitudinal roll bar above the seats protects the occupants should the vehicle roll over. Two 5.56 mm or 7.62 mm machine guns can be pintle mounted on top of the hull and these are normally positioned front right and left rear of the hull. Some vehicles have also been observed with twin 5.56 mm or 7.62 mm machine guns at each station, with the gunner being provided with a shield to provide some frontal protection from small arms fire. Standard equipment on the Buffel includes a 24 V, 7-pin trailer connection at the rear and a large fully enclosed stowage box mounted externally at the rear of the hull. A drinking water tank is also provided which is considered essential in the harsh environment in which the vehicle was designed to operate. |

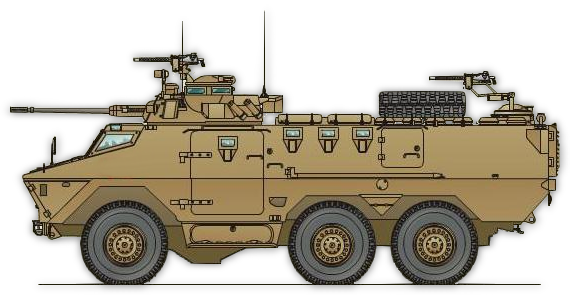

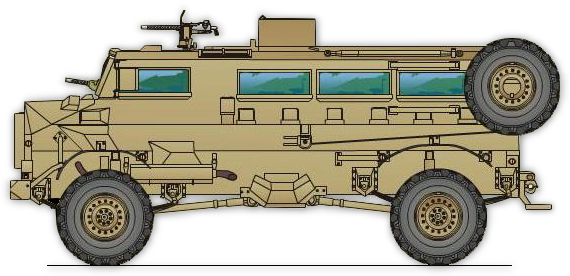

| Casspir Mine Protected Vehicle (MPV) |

|

The Casspir Mine Protected Vehicle (MPV) was one of the first MPVs to use the V-shaped monocoque hull, and is undoubtedly still the world leader in its field with more than 2000 in service in several countries. The Casspir has an enviable record as a life preserver in mine incidents. Casspir's mine protection, field repairability and maintenance qualities are legendary and it is currently the only general purpose MPV in service with a certified triple mine protection level for occupants and main components. Casspir is certified to protect its occupants against the effects of a triple TM-57 mine blast (21 kg of TNT) under any wheel, or a double mine blast (14 kg of TNT) anywhere under the hull. Standard ballistic protection is against 7.62 x 51 mm NATO and 7.62 x 39 mm (AK-47) ball ammunition. Protection against armour-piercing ammunition and the TMRP-6 self forming fragment mine are available as options. The Casspir's hull consists of a welded all-steel monocoque capsule, within which the main automotive and other components and systems are housed and to which the highly effective leaf spring suspension is attached. The design offers maximum protection to both occupants and main components, and also facilitates rapid field repair. In the standard APC configuration Casspir has two pneumatically operated armoured rear doors and a partially open roof with hatches above the driver and co-driver positions. A full armoured roof with hatches is available as an option. A variety of weapons can be mounted on the vehicle and firing ports are fitted below or in the armoured windows for the employment of personal weapons. Casspir is equipped with a Mercedes-Benz OM 352A engine, and a manual 5-speed transmission delivering drive to all four wheels. With a maximum speed of 85 km/h and excellent cross-country ability, Casspir offers excellent mobility for a vehicle in this class and a versatility that enhances the capabilities of a variety of forces in different terrain conditions. Casspir is the MPV of choice for employment in mine-infested areas by several security forces and by organisations employed in humanitarian operations.

Several variants are currently in service, all of which include triple mine protection for the occupants. These include ambulances, cargo vehicles, weapon platforms, command vehicles, tankers and recovery vehicles. |

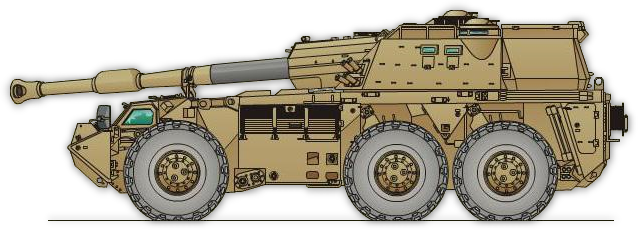

| G6 Rhino (Renoster) Self Propelled Howitzer |

|

The G6 is a proven, high mobile, wheeled, rapidly deployable, self-propelled, 155mm 45 calibers howitzer. It does not require any additional truck for long range transport. Using Base Bleed projectiles the G6 has a range of 39 km, with Denel's V-LAP projectile the G6 the range is extended to 50 km. It features a direct fire capability at ranges of 3,000 m. G6 armor offers protection for the 6-man crew against small arms fire and shell splinters. The G6 self-propelled howitzer carries 45 projectiles and 50 charges in the rear compartment with blow-off doors for increased safety. It is armed with a 7.62mm machine gun mounted on the turret roof for self-defense purposes. The G6 howitzer can fire all NATO 155mm ammunition and has a GPS navigation system to achieve improved accuracy. The use of a wheeled chassis instead of the traditional tracked chassis, means more reliability, increased mobility, a low maintenance and life cycle costs, and an extended service life. Development In the 1960s, the South African Artillery deployed three main artillery weapons, the UK 25-pounder Field Gun (G1), the 5.5-inch Medium Gun (G2) and the Canadian-built Sexton 25-pounder self-propelled gun. During early South African operations in Angola the poor range of South African artillery compared to opposing Russian-supplied 122 mm D-30 and 130 mm M-46 towed artillery weapons and BM-21 122 mm (40-round) multiple rocket launchers led to the fielding of the Denel Land Systems 155 mm G5 gun-howitzer and the SOMCHEM 127 mm (24-round) Valkiri multiple rocket system. While the towed G5 is perfect for many South African Artillery requirements, it does not have the cross-country mobility of the now BAE Systems Land Systems OMC Ratel (6 × 6) infantry vehicle which has been in service since 1976. The South Africans weighed the options of wheels or tracks for their new self-propelled artillery system and came down firmly in favour of wheels. The possible areas of operation of the G6 are likely to be some distance from their main bases, perhaps up to 1,000 km, and tracked vehicles have distinct disadvantages over long distances. Fuel consumption of a wheeled vehicle is a lot less than a tracked vehicle so less logistic support is required. The decision was therefore taken to choose a wheeled artillery system. The G6 prototype was completed in 1981 and shown for the first time in public in September 1982. By late 1986, four complete G6s had been built plus one additional turret. Of these four, two were considered as prototypes and two advanced development vehicles, for they incorporated many improvements as the result of user trials and changes in operational requirements. The first advanced development vehicle was completed early in 1984 and the second during 1986. There were four engineering development models completed during 1987 for final troop trials and confirmation of the modifications carried out on earlier vehicles. The first production G6s were completed during 1988, with Denel Land Systems being the prime contractor. BAE Systems Land Systems OMC delivers the chassis to Denel Land Systems which integrates the turret and delivers the complete system to the user. The production G6s were the first self-propelled howitzers with a full autonomous laying and navigation capability. As with the earlier G5, the G6 is a complete system and includes not only the vehicle but also the ammunition system, meteorological station, muzzle velocity analyser, fire-control system and a special artillery helmet radio communication system. Some of these systems have been in production for the G5 155 mm/45 calibre towed for some years. This support equipment is continuously upgraded or replaced by improved products. The G6 is deployed in batteries of six with the South African Artillery, each regiment having three batteries. In 1990, Abu Dhabi, part of the United Arab Emirates, placed an order for the supply of 78 G6 155 mm self-propelled howitzers with the first of these being delivered early in 1991. All have now been delivered and are organised into three regiments each of 24 weapons, with the remaining vehicles being used for training and war reserve. A comprehensive long-term product support package was also successfully delivered and implemented. Early in 1994, Oman placed an order for 24 G6 155 mm self-propelled howitzers, spares, logistic support, ammunition and a training package. All have now been delivered to Oman.

Late in 1996, it was disclosed that the South African National Defence Force had a total of 43 G6 systems in service under the designation GV6. |

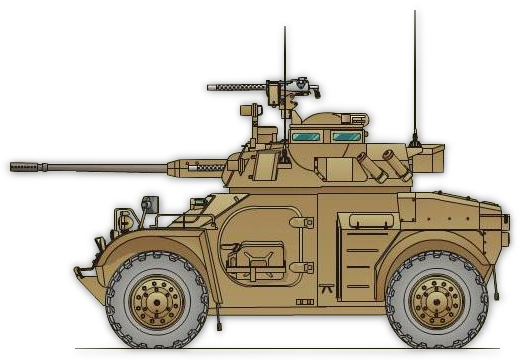

| Eland 20 Reconnaissance Vehicle |

|

In November 1961, South Africa concluded a contract with the French company Panhard for the supply of 100 AML (4x4) armoured cars armed with a 60 mm mortar and AA52 machine guns. An order was also placed for 150 Giat 90 mm DEFA gun turrets and components for a further 500 units. In January 1962, tenders were requested from 12 local South African companies for the manufacture of 350 Panhard AML armoured cars complete with turrets and 150 without turrets. Only four companies responded to the tender, which was subsequently awarded to Sandock Austral. The original South African Defence Force order was for 600 AMLs of which 100 came direct from France and the remaining 500 were locally manufactured. Of the latter, 350 were armed with 60 mm mortars, a coaxial 7.62 mm machine gun and a 7.62 mm antiaircraft machine gun and the remaining 150 were armed with a 90 mm gun. The first locally manufactured armoured cars, called the Eland Mk 2, were delivered in July 1963 and had a local content of 40 per cent. Between eight and 12 units per month were delivered for the following 16 months. The Eland Mk 1 was the version imported from France. The Mk 2, 3 and 4 versions of the Eland all had an imported Panhard petrol engine which was air cooled. The Mk 2 had an improved steering system, the Mk 3 had an improved brake system and the Mk 4 had an updated fuel system and an electrical clutch. Although the three versions are similar externally they are different internally. The Mk 5 was the first version with a locally built engine, this was a 2.5 litre water-cooled petrol engine which could be changed in the field in 90 minutes. It also had locally developed hydraulic clutches, communications equipment, springs, shock-absorbers, wheels and run-flat tyres. During 1972-73, the assembly of 356 Eland Mk 5 armoured cars was completed and delivery was at the rate of 24 vehicles per month. A programme was then completed during 1974-75 for the repair and conversion of earlier Elands, which included a complete rebuild of the vehicle, general repair work and overhauls which converted the vehicle to the Mk 6. This programme involved the conversion of a total of 1,016 vehicles. The final version of the Eland was the Mk 7, which was introduced in 1979. It has new power brakes, an increased storage capacity resulting from the slightly longer chassis, inclusion of a fresh water tank and a more comfortable driver's compartment. External modifications include a towbar at the front, halogen lights on the mudguards and the commander's cupola with armoured glass windows which allows the commander to see through a full 360°. South Africa also made the complete 90 mm gun for the vehicle as well as a 60 mm mortar, machine guns, optics and ammunition. Production models of the Eland were armed with a 90 mm gun/7.62 mm coaxial and 7.62 mm anti-aircraft machine guns or a 60 mm mortar and a 7.62 mm machine gun. A model with a two-man turret armed with a 20 mm cannon and a coaxial 7.62 mm machine gun was also produced. A number of this last version were supplied to Morocco.

Ninety-five per cent of the Eland was produced in South Africa by the time production was completed. Total South African production of the Eland amounted to approximately 1,300 vehicles. |

| R1 Battle Rifle |

|

The R1 was essentially a South African copy of the Belgian Fabrique National FN-FAL battle rifle design including overall dimensions, construction methodology and performance specifications. It proved a hardy weapon for the bush wars required of it and was as reliable and well-liked as its foreign counterpart. As it followed the FN FAL to a tee, the R1 was also chambered for the large and powerful 7.62 x 51 mm NATO standard cartridge which gave it good accuracy and penetration abilities at range. The firing action remained the widely accepted gas-operated, tilting breachblock system and the R1 fired from a 20-round straight detachable box magazine as in the FN FAL. Sighting was through an aperture rear sight and front post sight out to 600 meters. Some 30,000 South African R1 rifle examples were also shipped to purchasing Rhodesia. Over time, production and operational use of the R1 broadened considerably to the point that the rifle family line incorporated various other useful guises. While the family already included the base R1 service rifle, there soon came the "R2" with its folding buttstock for a more compact offering. This was followed by the "R3" with its semi-automatic fire only mode (intended for police and security forces), the "R1HB" with its heavy barrel and bipod for the squad-level fire suppression role, the "R1 Sniper" accurized repeating fire weapon system and the "R1 Para Carbine" with its integrated IR sight, shortened barrel and more compact length. The "R4" of 1975, while following the same designation pattern of the R1 before it, was based on the Israeli Galil assault rifle, the "R5" being a shortened carbine form of said model. Specifications:

Source: MilitaryFactory.com |

| R4 Assault Rifle |

|

The R4, a standard issue for all soldiers, is a South African assault rifle with a folding stock and 5.56mm calibre. It was developed to replace the aging R1 (a variation of the FN FAL). This weapon first saw active service in South West Africa (Namibia) and in raids into Angola and other neighbouring southern african countries in the late 1970s. The R4 is partly based on the famous Israeli Galil rifle and is still in service in all the branches of the South African Defence Force. Specifications:

|

| FN MAG Light Machine Gun |

|

MAG stands for Mitrailleuse d'Appui General which is Belgian for General Purpose Machinegun. It was developed by the famous Belgian company FN Herstal in the 1950s as a true universal machine gun that could be used as a light MG on bipod, as a medium MG on tripod or as a vehicle-mounted and coaxial MG on helicopters, armored cars and tanks. The basic design used as much steel stampings and pressings as possible to save the labor and costs, and the final gun had the angular, but very business-like appearance. By no way a beauty, it is extremely reliable and a proven design that has seen widespread service in many armies around the world, including Belgian, British, Australian, Canadian, and the USA. Specifications:

|

| 40 mm RPG-7 (Rocket Propelled Grenade) |

|

The RPG-7 is one of the most common anti-tank weapons in the world, and in Angola, the communist backed forces made extensive use of this simple, yet effective weapon. Due to the large amounts of weapons captured by the SADF in successful cross-border operations, South African troops operating in enemy territory were often trained in the use of the RPG-7. Although designed as an anti-tank weapons it's characteristics make it an ideal weapon for terrorist attacks against civilian VIP targets. It can also be used as an effective anti-sniper weapon within its 300 meter flat trajectory range. The RPG-7 is, along with its successor, the RPG-16, the main weapon of the Soviet soldier against enemy tanks. They are supplemented by the RPG-18, a copy of the M72 66 mm light anti-tank weapon used by US and British forces. The RPG-7 has a long combat record, where, in the 1973 Middle East War, they destroyed more Israeli tanks on the northern front than any other weapon. The Israelis themselves have adopted large numbers of captured RPG-7s and have designed and produced a similar weapon. In Afghanistan, where the Afghan Resistance used both Soviet and Chinese built versions of the RPG-7, the Soviets lost many tanks to these recoilless RPGs. Specifications:

|

| MEERKAT 40 mm MGL (Multiple Grenade Launcher) |

|

The Meerkat (Milkor MGL-MK1) is the premier multiple grenade launcher of the world. Made in South Africa, the Milkor MGL gives its operator 6 rounds of 40mm low-impulse grenades at his immediate disposal, making it an extremely effective force multiplier for any special operations team. It is the preferred multiple grenade launcher of Spec-Ops and mercenary forces around the world. One of the features that makes the Meerkat such an effective combat weapon is the Armson Occluded Eye Gunsight that the weapon employs. The sight is used with both eyes open making accurate shots a snap. Specifications:

|

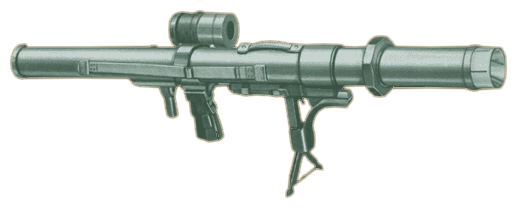

| LRAC-89 Anti-Tank Free Flight Missile Launcher |

|

The extensive use of plastics has led to the development of a low-weight anti-tank weapon with considerable strike effect. The launcher consists of the launch tube on which an adjustable shoulder piece foregrip, electrical firing mechanism and telescopic sight are mounted. The rocket is carried in a container, which is fitted directly into the tube, thus extending its length and ensuring that all of the propellant is burnt before the missile leaves the muzzle. All the required electrical connections are made as the round is loaded. The propelling charge is of the 'brush' type, in which a number of sticks of propellant are supported by perforated disks at each end. Due to the small spaces created between the individual sticks, faster and more even burning of the propellant is achieved. The rapid burning propellant does not leave exhaust particles and ensures a high muzzle velocity. The fin-stabilised rocket is pre-packed in a discardable launch canister, which can be fired in all weather conditions. The launcher is reusable and has a life in excess of 200 firings. Burnout of the rocket is achieved inside the launcher, thus eliminating the need for protective clothing. The HEAT warhead is capable of penetrating 650 mm of rolled homogenous armour steel, making it capable of destroying main battle tanks from any angle. The missile was developed by Sonchem jointly with France and Germany, and was battle tested in Angola during the 80's. Specifications:

|

| Headgear - Bush hat and kevlar helmet |

|

| The headgear used in the SADF was optimized for use in the South African bush. The floppy bush hat (left) helped keep the sun out, and also particularly noticible is the sun-flap on the nutria helmet cover. The form and proportions of the helmet resemble that of the old pith helmet used by British colonial forces |

| M83 Tactical load bearing vest (Gevegsbaadjie) |

|

This fully padded battle-jacket was developed in South Africa for the South African Defence Force in the early eighties and proved so successful in the hostile environment of the South African bush that it's design has since been adopted by many armies around the world. The vest pouches were made of tough brown texturised nylon with twin zip closing rear cargo pockets that could carry a clansman PRC 320 Radio. Each side had huge buckle fastening cargo pouches and eight R4 mag pouches, as well as grenades and ffd's could also be carried in the nine velcro closing front pouches. There were also numerous accessory loops, attachment points and a map pocket. |